What Structure of Shipping Box Is Easier to Assemble Quickly?

We've all experienced the same moment of frustration. You've got the product ready to ship, and then you reach for the shipping box, and it's lying flat and uncooperative on the table. Nobody ever remembers the folding sequence or gets the tape on the first time. It's the small things that can bottleneck the entire packaging process. When every second counts, shipping boxes that can be assembled without hassle directly improve customer satisfaction and reduce operational costs. Instead of working faster, it's about working smarter. It's about choosing boxes designed for faster and easier manual box assembly.

Speed Comes from Simplicity of Design

All of the fastest boxes to pack are the most simple. Complexity is the enemy. While regular slotted containers (RSCs) are the most basic style of boxes, they work. Cheap, well-made, typically-constructed boxes that are designed with embossed creases will pack quickly due to their performance. All boxes with regular slotted construction are supposed to unfold and take a basic shape of a box, one of the easiest packable structures. A simple box shape and a consistent mechanism and construction saves packers from the question of how to assemble. The first box style that will save the most time on the packing line is one with basic construction and a simple mechanism.

Shipping Boxes with Ease

Think of the difference between the shipping boxes that require instruction with the boxes that are designed to fold quickly with little to no instruction needed from the user. When designed with brilliant engineering in mind, boxes can practically fold themselves. With folds that require little effort to crease, flaps that are designed to line up, and printed instructions to simply "Fold Here," assembling boxes is fast and easy.

This is the incredible value gained from suppliers with a professionally designed team. Instead of fulfilling a simple order of shipping boxes, they are able to create boxes that require little time to assemble, saving time and effort that can be better utilized elsewhere. With a minimal learning curve, even the newest staff members can process a shipment with minimal effort. This transforms a standard shipping box into an impactful shipping container that streamlines processes and improves the workflow efficiency.

The Right Strength Without the Struggle

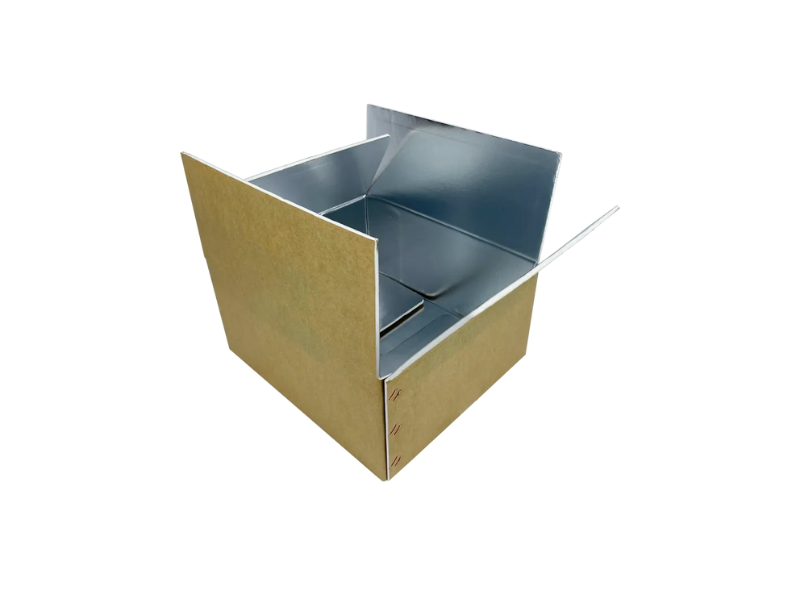

Can a shipping box work if it's only fast? No, it's a waste of time and assembly. The biggest hurdle is getting the needed durability and weight. The answer is material and strategic design engineering. For instance, if a box is made from better, stiffer, and heavier grade corrugated board, the box will hold its shape as soon it's folded and will provide better protection for insulated food containers and other fragile items.

Strength, not complicated design features, is built into the boxes' materials and geometric design. For heavier weighted boxes, double-walled construction can be used, and strategic reinforcements ever has to increase assembly time. As such, no business has ever compromised the speed of box assembly for the protection of the items incide, and they will always be confident their goods will arrive safely.

True Efficiency With Customization

Although bigger boxes can often do the job, a custom-designed shipping box is often the key to rapid efficiency in assembly and logistics overall. Boxes specifically made for the products do not waste time or materials. There is no need to fill the box with padding, or deal with the extra hassle of overpacking some parts and underpacking others.

A good packaging partner is able to assess the product's dimensions, weight, and travel destination to design an optimal box structure. This may involve creating a box with a shallower depth for flat items, which uses and takes less time to assemble. Or, answer implementing a specifically designed closure for the lid that is easy to secure. If a box is perfectly designed to hold a product, every step in assembly becomes much more faster and cost efficient. This shipping box can then be regarded as more than just a container, instead a vital tool for the operational efficiency of the company.

To end with, the quickest shipping box to put together is one that has simplicity and purpose in its design. It's box that has a structurally simple design, is helped by intuitive instructions, gains strength through careful tactical material selections, and reaches its peak optimal configuration when tailored for the exact product. By concentrating on this design, companies can transform the ordinary, monotonous process of box assembly from a time-sucking, click clerk to a quick, smooth step in the process of shipping and delivering orders to customers.