How can foldable cold chain cardboard boxes save 40% on warehousing and reverse logistics costs?

Re-evaluating the Model of Cold Chain Containers

Before anything else, logistics comprise one of the most important and calculated operations in the world, particularly in a temperature-sensitive environment. The traditional cold chain shipping method uses a lot of rigid and fixed-form containers, which include foam coolers, heavy-duty wax-coated boxes, and bulky plastic totes. While these containers are effective for insulation, they create many logistical problems before and after the containers’ primary journey. For instance, these containers take up a lot of space in warehouses when they are empty, it is expensive shipping them back to the origin due to their bulk, and they are often un-useful and discarded after a single shipment. Consequently, after a shipment, they create waste and recurring costs. In truth, the benefits of saving almost 40% in the costs associated with warehousing and logistics are not just a marketing tactic, but are indeed the results of thinking outside the box and looking for a reasonable solution. The answer is moving away from a static, one-trip vessel to an active, intelligent asset. This is where the innovative design of foldable cardboard boxes comes in.

The Magic of the Fold: Lowering Cost of Storage and Transport

The core innovation is surprisingly simple: a box that reduces its volume when empty. Consider a box that is the size of a standard rigid cooler – it will be about one cubic foot of space. Now think about the cooler being a flat-packed panel or a small folded bundle that takes up 80% less space. This one change reduces upfront cost significantly. For a business that needs to store thousands of containers, the cost of overhead is tied to the amount of warehouse space is being rented. Flat folded, collapsible cold chain cardboard boxes do significantly reduce the amount of storage space that is taken up. The space that is opened up can be used to store a different inventory and even downsize warehouse space requirements. In addition, box transport cost is also significantly reduced when the coolers do not need to be transported as empty containers. You are paying to transport a bundle of coolers, not truckloads of empty, bulky coolers, so the cost for this inbound logistics leg of empty packaging is offset and adds to a significant cost savings at the end of the day.

The Return Journey and Lifecycle

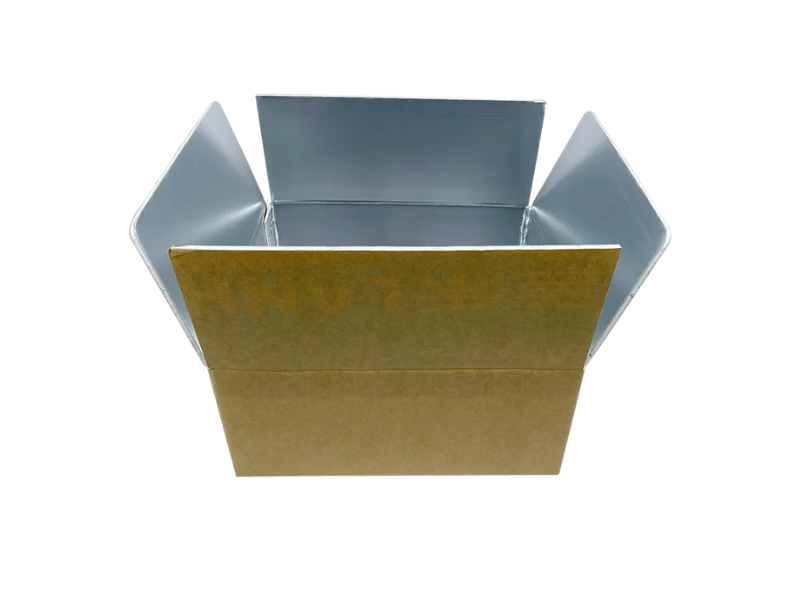

Managing the return flow is the next economic breakthrough with reverse logistics. In circular systems such as reusable containers for meal kits, pharmaceutical samples, and high-value food distribution, return of the empty container is a must. There is a massive difference in cost – more than a 60% return cost – if you consider the return of a flat, collapsed box compared to a bulky, rigid container. The economically viable models of reuse systems make return boxes easy and economically attractive. Returnable boxes encourage reuse and the recovery of the initial boxes. The returnable boxes on the other hand are designed for multiple cycles. Their construction is from robust, corrugated cardboard with insulating liners, sometimes reflective, and thin foam sheets. If designed properly, these boxes are durable and lightweight, extending the container life over several trips and drastically lowering the packaging costs on a per shipment basis, it lowering the cost of return boxes. There is more to the overall 40% economy than the returnable box design. There is more than 40% economy in the entire system of returnable boxes with thin, lightweight, durable containers. There is a system of thin, durable containers, designed for easy assembly, that results in more than a 40% economy. There are thin, lightweight, durable containers designed for easy assembly that result in the system of 40% economy. There are containers with thin, lightweight, durable systems designed for easy assembly that result in more than 40% economy.

Crafting a Smarter & Leaner Supply Chain

Beyond cardboard boxes direct storage and freight savings, theres gaining a more responsive and lean supply chain. Having lightweight boxes reduces shipping weight when fulfilling outbound orders, which translates to fuel and freight savings. Their flat-pack format allows for just-in-time inventory management of packaging. You do not need to preassemble and store large quantities, saving labor and storage space. In the case of product recalls, or reverse shipping (like expired goods), the same efficient streamlined return process works, and loss is minimized. For business partners looking to elevate their brand, boxes contain a high-quality surface and printable instruction branding, converting a logistical asset into a marketing touchpoint. It is also more sustainable because most packs contain recyclable and certified materials. In the end, optimizing the business model is more than just buying a box. It comes to working with a packaging expert who can see the complete cost picture. A skilled designer can produce a box with intuitive folds and locking mechanisms to seal assemblies that sustain their thermal performance. It proves that design is the best insulator against operational waste and unnecessary negatives.